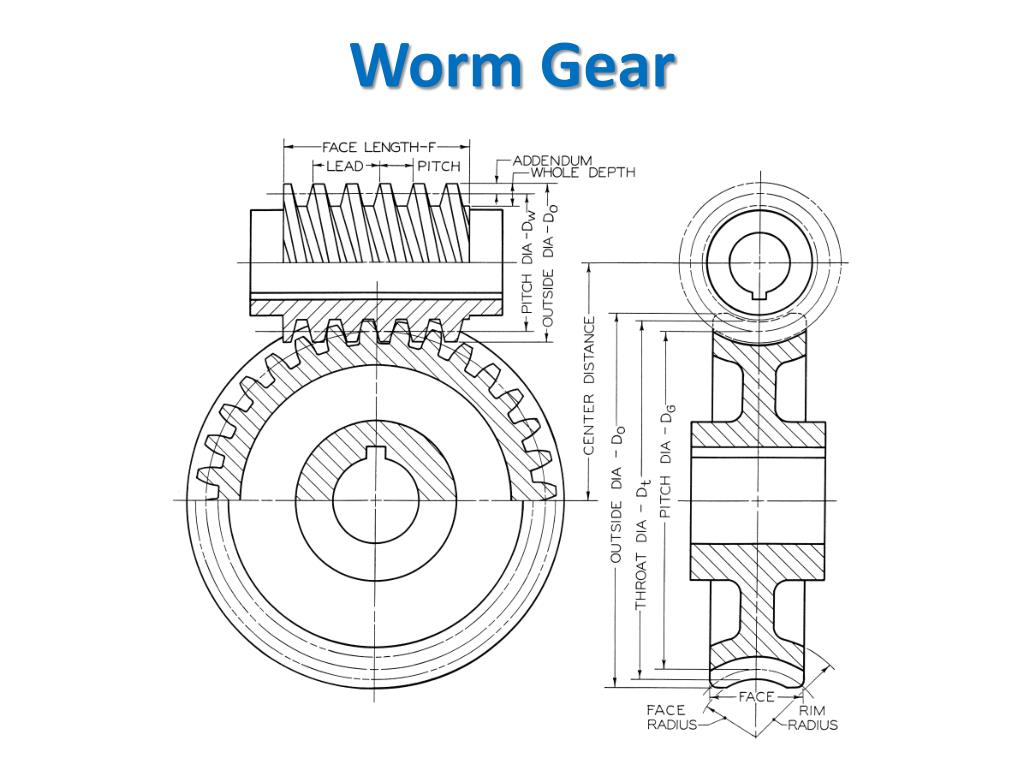

In these widely used speed reducers, a worm gear drives a worm wheel to provide output motion at a right angle to the motor shaft, Figure 2. Here’s a brief description of some common types and their relative efficiencies.

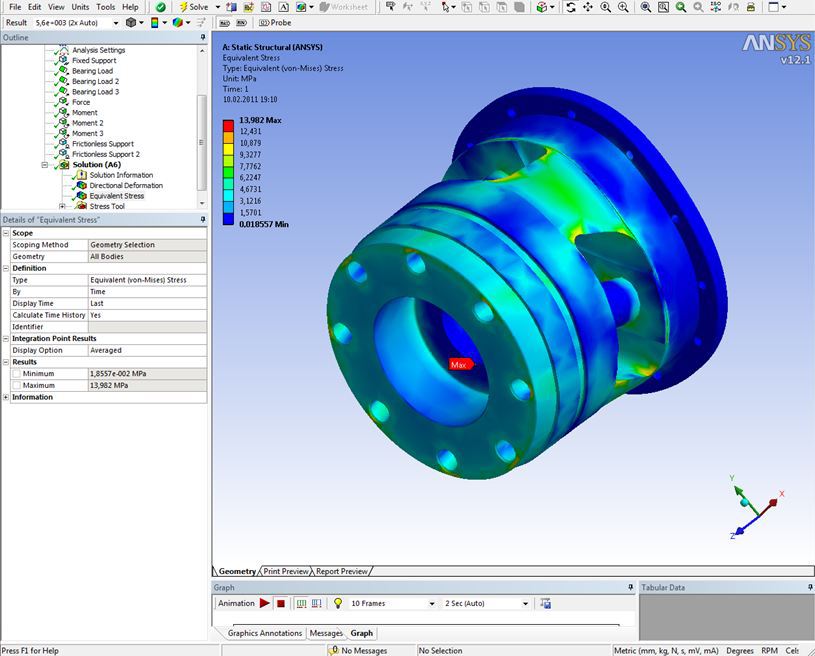

This efficiency ranges from 49 to 98%, depending on the type of reducer and number of reduction stages it contains, Figure 1. Though reducer efficiency may vary slightly from one manufacturer to another, the way in which the gears intersect and mesh mainly determines speed reducer efficiency. This file type includes high resolution graphics and schematics when applicable.

Therefore, you should know how efficiently the various types of reducers use incoming motor power to drive a load. Because they are widely used with industrial equipment, speed reducers and gearmotors can significantly impact your drive costs.

0 kommentar(er)

0 kommentar(er)